-40%

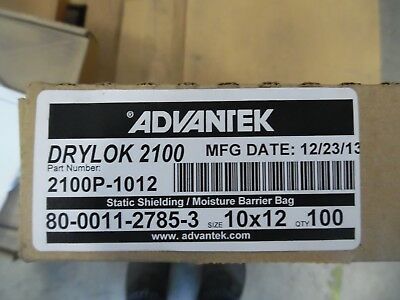

DRI-SHIELD 2000 DRYLOK 2100 STATIC SHIELDING MOISTURE BARRIER BAG 10"x12" 100 PK

$ 9.5

- Description

- Size Guide

Description

DRI-SHIELD 2000 / DRYLOK 2100 Static Shielding / Moisture Barrier Bag, 10” x 12”, 100 bags per pack. Bags are marked DRYLOK 2100 and with the Advantek corp name. Manufactured by SCS (formerly 3M Static Control). Mfr item SCS-60527.These bags are engineered to protect contents from electro-static shock and moisture. Durable 6 mil construction prevents punctures, safeguards static- and moisture-sensitive devices during transport and storage. Designed to contain ESD sensitive items and items susceptible to moisture damage. Low Water Vapor Transmission Rate for superior protection for moisture-sensitive device.

This foil moisture barrier bag provides protection for ESD sensitive and moisture sensitive electronics, typically SMT (Surface Mount Technology) items. Best practice is to use with Desiccant and a Humidity Indicator Card. A nylon layer helps to strengthen the bag. The bags are heat sealable and suitable for vacuum packaging. Bags are printed with ESD protective and moisture sensitive warning symbols, and a lot code for traceability.

SCS Moisture Barrier Bags Dri-Shield

®

3000 are manufactured from a laminate of nylon, foil, and polyethylene. The metal layer provides discharge shielding and minimizes the penetration of electric fields and electrostatic discharges.

Meets ANSI/ESD S20.20, Packaging standard ANSI/ESD S541,

Static Control Bag ANSI/ESD S11.4 Level 1, and IPC/JEDEC J-STD-033.

Item may be returned only with an RMA (Return Material Authorization).

This eBay store is no longer accepting payment via PayPal, but we have an easy and secure process for accepting credit card payments and arranging delivery. Just Click Buy, we will send you an email to confirm shipping info eBay has given us. Once information is confirmed a customer service representative will contact you.

Physical

Typical Value

Testing Method

Moisture Vapor

Transmission Rate

(MVTR)

<

0.0003 grams/100 sq. in./24 hrs

<

0.002 grams/100 sq. in./24hrs

ASTM F1249

ASTM F392 condition E and

ASTM F2149

Tensile Strength

3800 PSI, 26 MPa

ASTM D882

Puncture Resistance

16 lbs, 71 N

MIL-STD-3010C Method 2065

Seal Strength

15 lbs, 66 N

ASTM D882

Thickness

6 mils, 0.006" +/-10%

MIL-STD-3010C Method 1003

Marking Adhesion

Pass

IPC-TM-650 2.4.1

Electrical

Typical Value

Testing Method

ESD Shielding

<10 nJ

ANSI/ESD STM11.31

Surface Resistance -

Interior

1 x 10

4

to < 1 x 10

11

ohms

ANSI/ESD STM11.11

Surface Resistance -

Exterior

1 x 10

4

to < 1 x 10

11

ohms

ANSI/ESD STM11.11

EMI Attenuation

45 dB

1 to 10 GHz

Cleanliness

Typical Value

Testing Method

Silicone

Not Detected

FTIR

Heat Sealing Conditions

Typical Value

Temperature

400°F, 204°C

Time

0.6 – 4.5 seconds

Pressure

30 – 70 PSI, 206 – 482 KPa